About the project

A Holistic Digital Mine 4.0 Ecosystem is a project focused on industrialization, informatization and sustainable development of the mining sector. We aim to provide solutions that will build a novel mining digital ecosystem and a systemic structure for the implementation of Industry 4.0 in mining industrial environments. MINE.IO solution will embrace the whole mining system value chain from resources’ exploration, extraction, and processing to waste management and post mining activity.

Subscribe to our Newsletter here!

Take a look at the MINE.IO events calendar

25

7 Pilot Use Cases

€ 14M

42 months

Demonstrations

The MINE.IO ecosystem will be tested in various demonstration sites in 5 EU countries, including 4 active mine facilities and 2 historic mine sites, where 21 technologies will be tested.

Our core idea is to provide a manufacturing system architecture for use on the “shop floor” of digital twin mining in a cloud environment. MINE.IO promises a cutting-edge cloud services infrastructure and a cutting-edge mining ecosystem of sharing, connectivity, and unrestricted collaboration. To encourage openness and data sharing, MINE.IO will provide a uniform data infrastructure and collaborative platform ecosystem that will enhance the climate for collaboration among mining companies. MINE.IO aims to improve the standardization of the fundamental operations in the mining sector, including asset and process equipment optimization, embedded predictive analytics, optimization techniques based entirely on data, integrated cyber-virtual and cyber-physical systems, automation and robotization of mining exploration and production processes, sustainable mining, and post-mining management.

MINE.IO will offer a resource optimization and digital transformation framework, including particular circular economy and “low-impact mining” solutions to address the growing social and environmental issues. Energy advancements, such as the switch to autonomous electric vehicles, will provide socially responsible profit while enhancing the working conditions for front-line employees, including better air quality for those who work underground.

Pilot site 1: Germany

Involved partners: TUB (lead), ICCS, LTU

Location: Digital TSL-Smelter at the Institute of Nonferrous Metallurgy – Freiberg, Germany

Involved partners: TUB (lead), LTU, subcontractors (mecorad GmbH and Bundesanstalt für Materialforschung und -prüfung)

Pilot site 2: Poland

Involved partners: KGHM (lead) Ł-ITR, Ł-EMAG, AGH, LTU

Pilot site 3: Greece

Involved partners: AMDC (lead), ACC, HMU, USAL

Pilot site 4: Finland

Involved partners: UOULU

Pilot site 5: Sweden

Involved partners:

Pilot site 6: Portugal

Involved partners: INE (lead), MUO, WRCP

Partners

Latest News

VI General Assembly of the MINE.IO Project Held in Porto

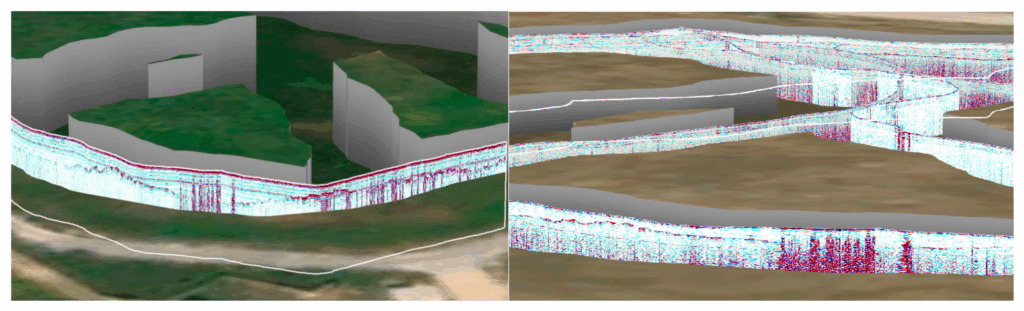

Ground Penetrating Radar for the Exploration of Complex Mining Contexts

Shaping Future Standards: Highlights from the 3rd Smart EcoMine Hub Workshop

MINE.IO Events Calendar

Find out what events we are planning to organize and what events you will be able to meet us at.

Help us evaluate what you would expect from us at some of them. Register for events with our participation.

Familiarize yourself with those that have already taken place. Read the reports and summaries we have prepared for you.

Subscribe

to Our Newsletter!

Sign Up to get the latest news and stay updated