First MINE.IO Technology Exhibition and Pilot Tests

Introduction

The second year of development work on the use of the innovative technologies developed as part of the Mine.io project has led to the technological readiness of the selected solutions at a level sufficient for real-world testing on industrial pilot sites. Thanks to the results obtained from the tests carried out, it has been possible (and will continue to be possible) to further improve the technology both in the project partners’ laboratories and at pilot sites.

The first demonstrations and exhibitions were held, during which it was possible to see the selected solutions live and find out how the work and tests leading to their presented state of technological advancement looked like.

Example of solutions and technologies tested and exhibited

Technologies: Drone monitoring systems, sensor integration, and data fusion

AUTOMATION and ROBOTICS EXPO 2024 in Athens

AUTOMATION and ROBOTICS EXPO 2024 brought together leading automation and robotics experts and innovators in Athens from 12-14 April 2024. Among them, ACCELIGENCE, a significant member of the MINE.IO project consortium, showcased advanced drone technology with a wide range of applications, equipped with a dedicated embedded platform.

These drones are a key component of the MINE.IO project, which aims to bring high-tech solutions to the mining industry to increase its productivity and safety. The presentation of this unmanned aerial vehicle at the Athens International Fair highlighted the strategic importance of the project and its potential to drive innovation in the sector.

The MINE.IO project was an important highlight of ACCELIGENCE’s presentation at the fair, underlining the company’s commitment to the development and implementation of new technologies. AUTOMATION and ROBOTICS EXPO 2024 provided an excellent platform to demonstrate the capabilities of drone technology and engage in discussions about the future of technology in the mining industry and beyond.

Workshop Exhibition in Luleå University of Technology – November 2024

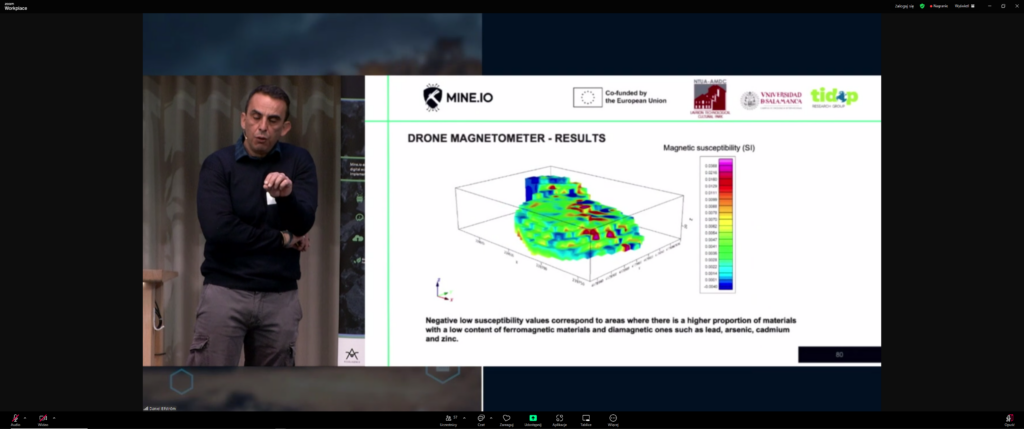

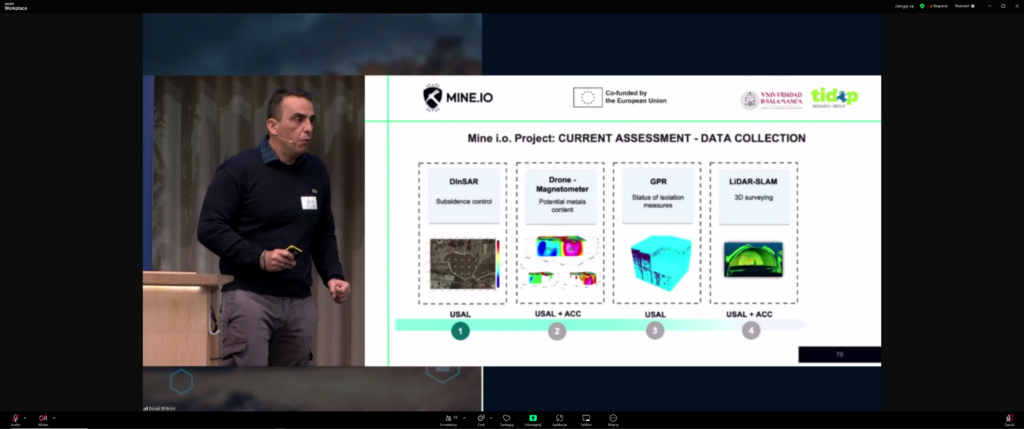

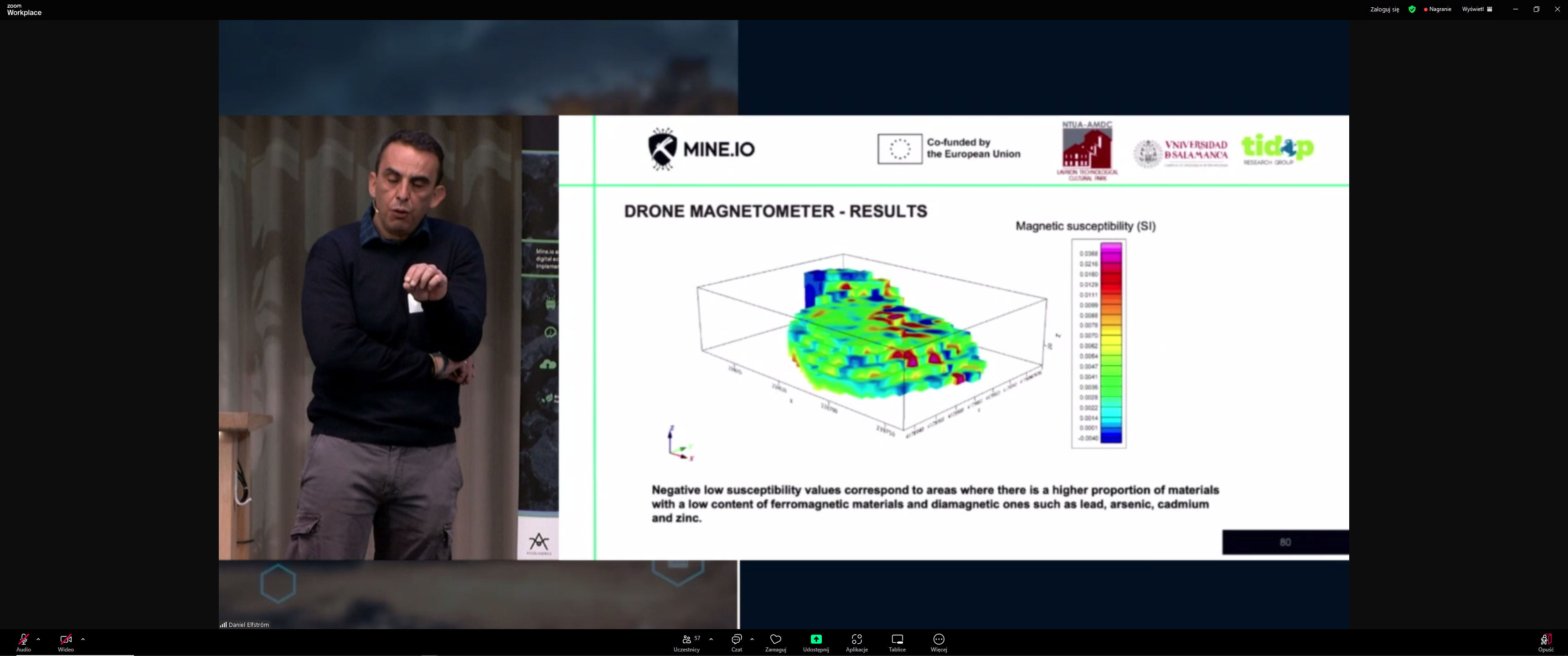

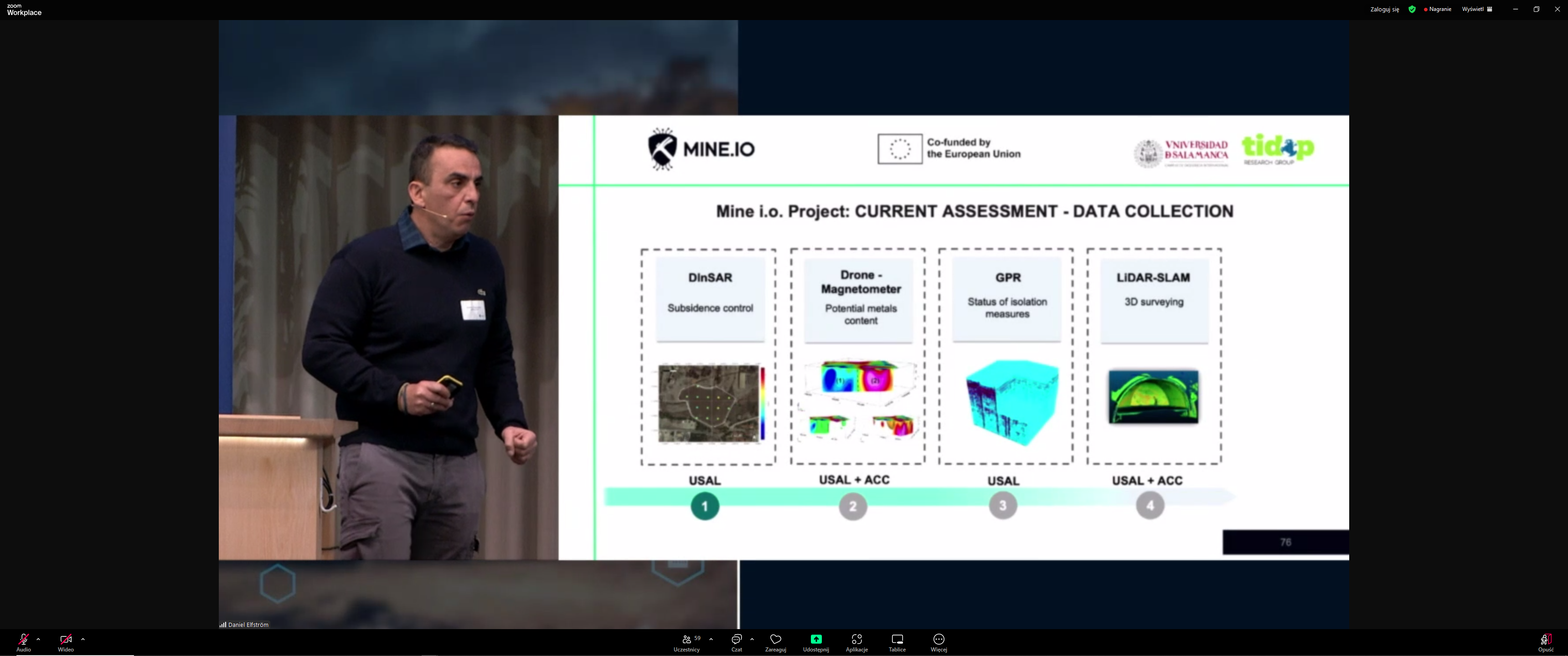

In between sessions during the Mine.io Workshop, there was time to view a video that highlighted selected technologies being developed within MINE.IO project. The exhibition included a demonstration of the test use of drones equipped with hyperspectral cameras, which, combined with advanced drone magnetometry and advanced satellite methods (e.g. InSAR) and GPR, allowed for the accurate characterisation of the area of waste deposits surveyed at the Lavrion pilot site. Viewers were guided through the exhibition at Lavrion by Diego Gonzalez Aqulera, Katerina Margariti and Vasileios T. Protonotarios

This technology allows data on metal concentrations to be collected, land subsidence movements, water ingress, and the condition of the containment layers to be assessed. The data collected in the relevant repositories can be subjected to advanced analysis to support environmental management and risk assessment.

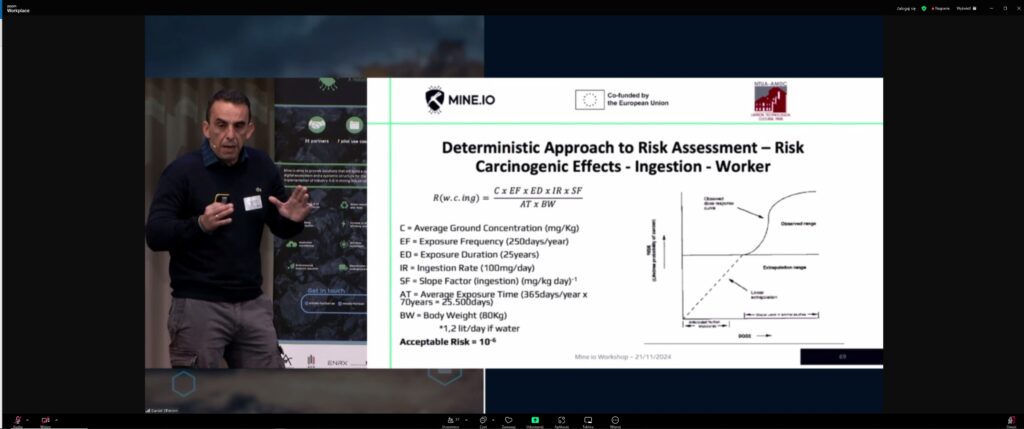

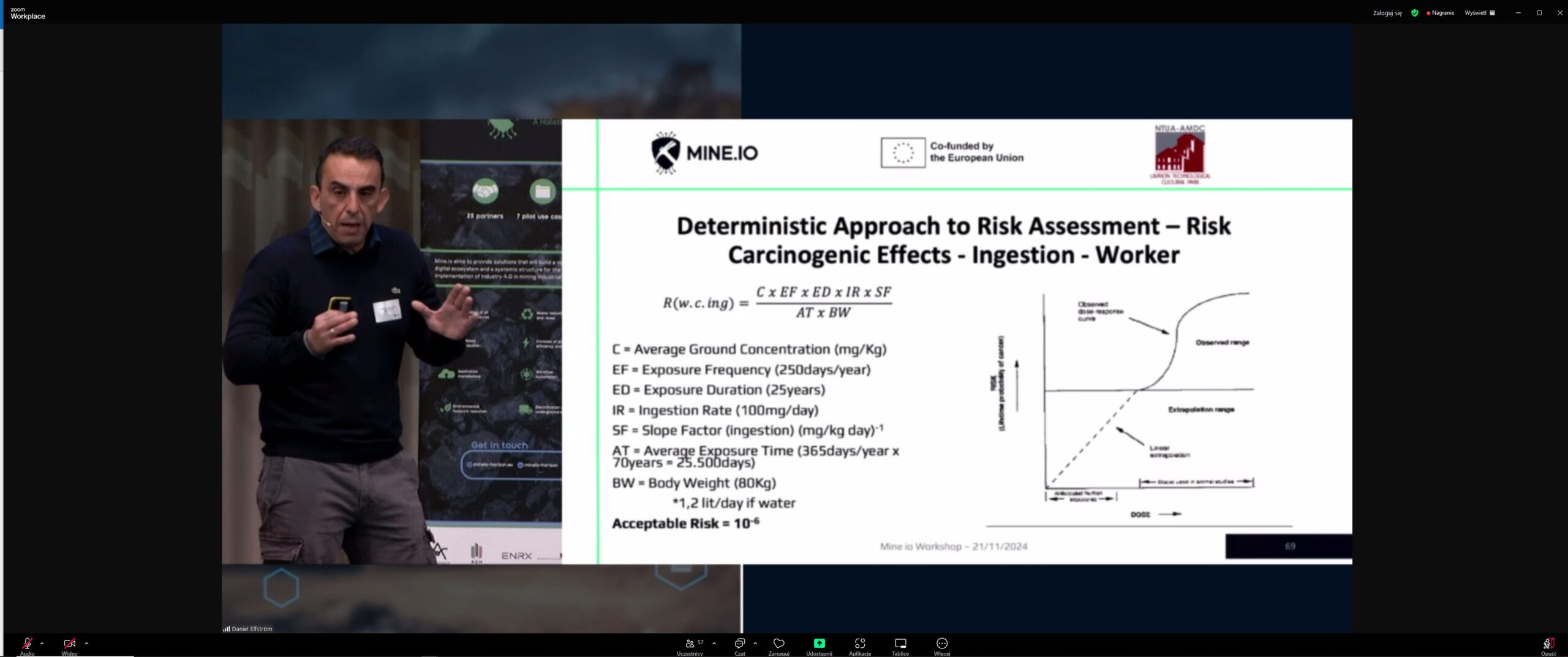

In addition, during his workshop lecture, Dr Vasileios Protonotarios talked about the positive impact of using these technologies to manage risk in post-mining areas and the benefits of recovering valuable minerals from waste deposits through their use.

In addition, during his workshop lecture, Dr Vasileios Protonotarios talked about the positive impact of using these technologies to manage risk in post-mining areas and the benefits of recovering valuable minerals from waste deposits through their use.

dddd

Example of solutions and technologies tested and exhibited

Technologies: ML and AI tech optimize flotation process control in mineral plants

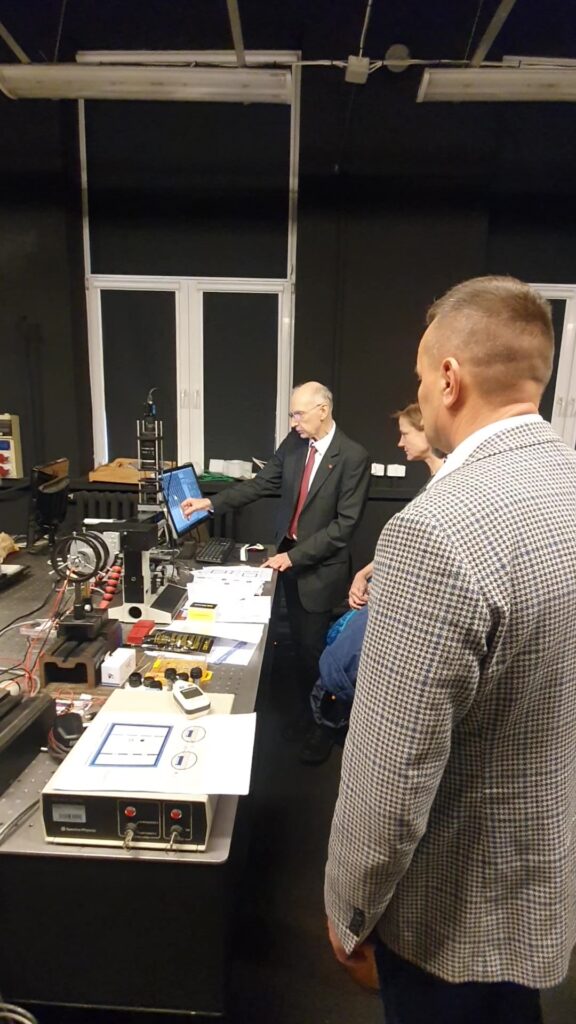

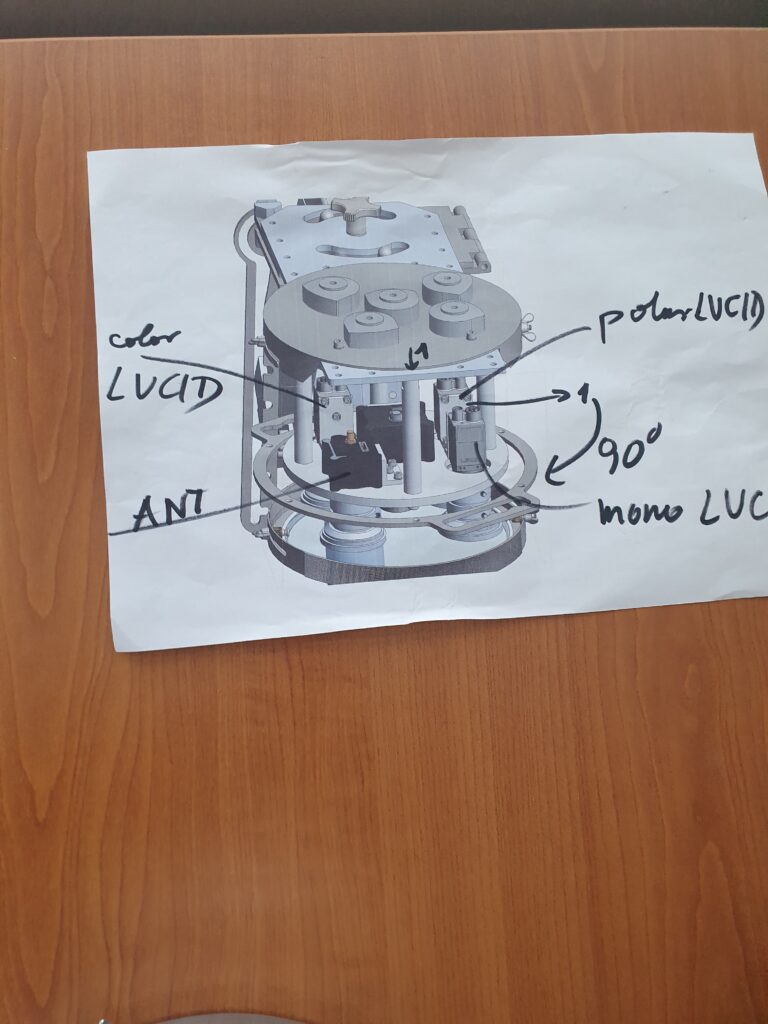

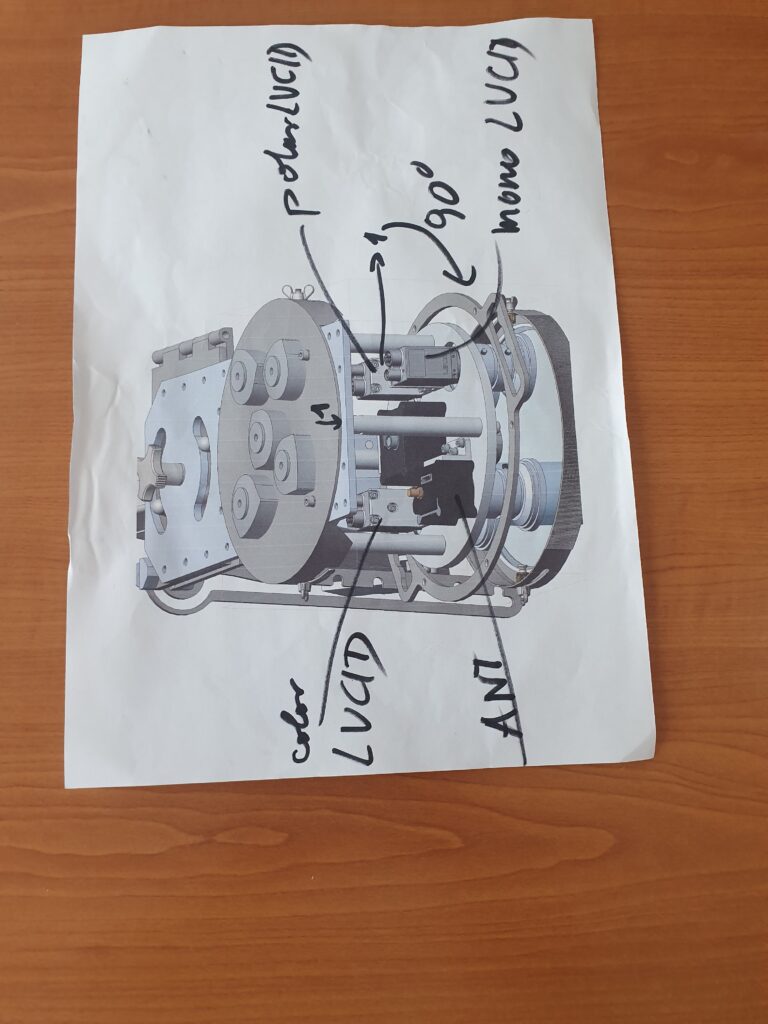

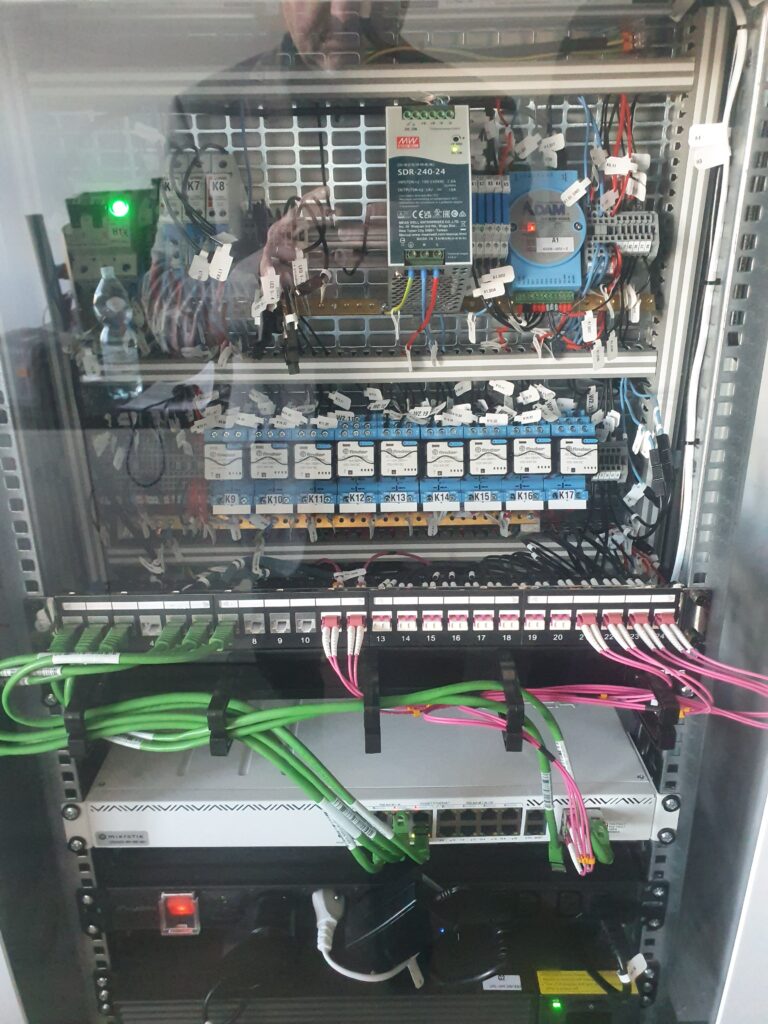

PIT system exhibition at the Łukasiewicz-ITR research institute

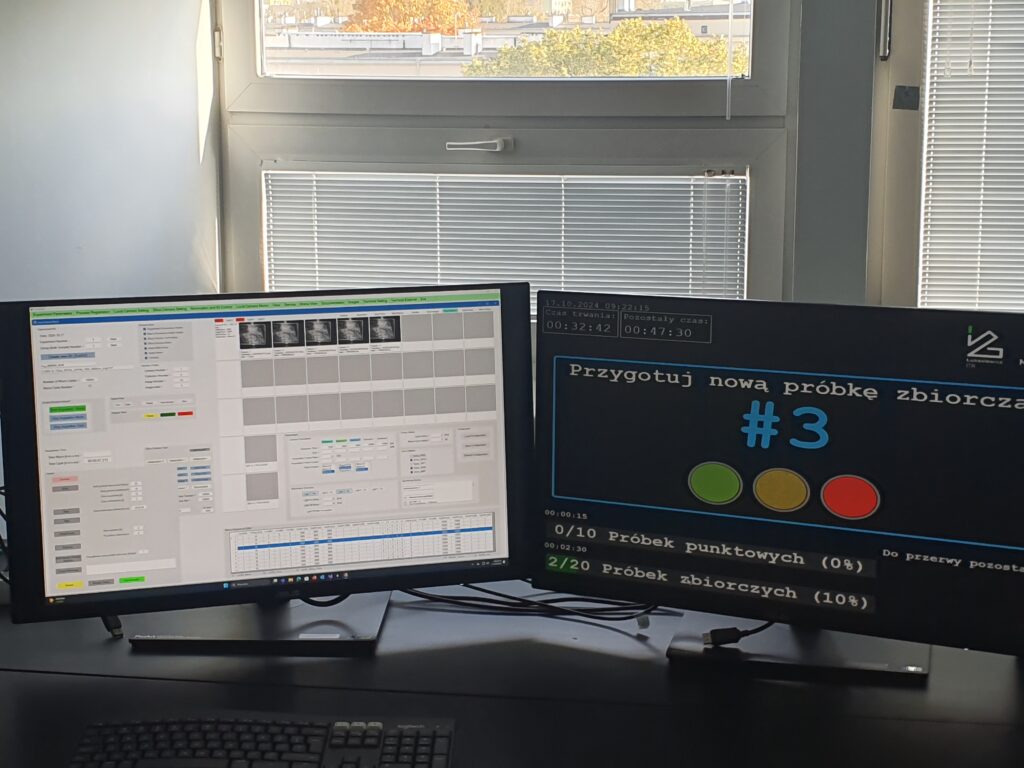

The laboratory version of the PIT system was presented at an exhibition held in the Institute’s laboratory and positively evaluated by, among others, employees of KGHM.

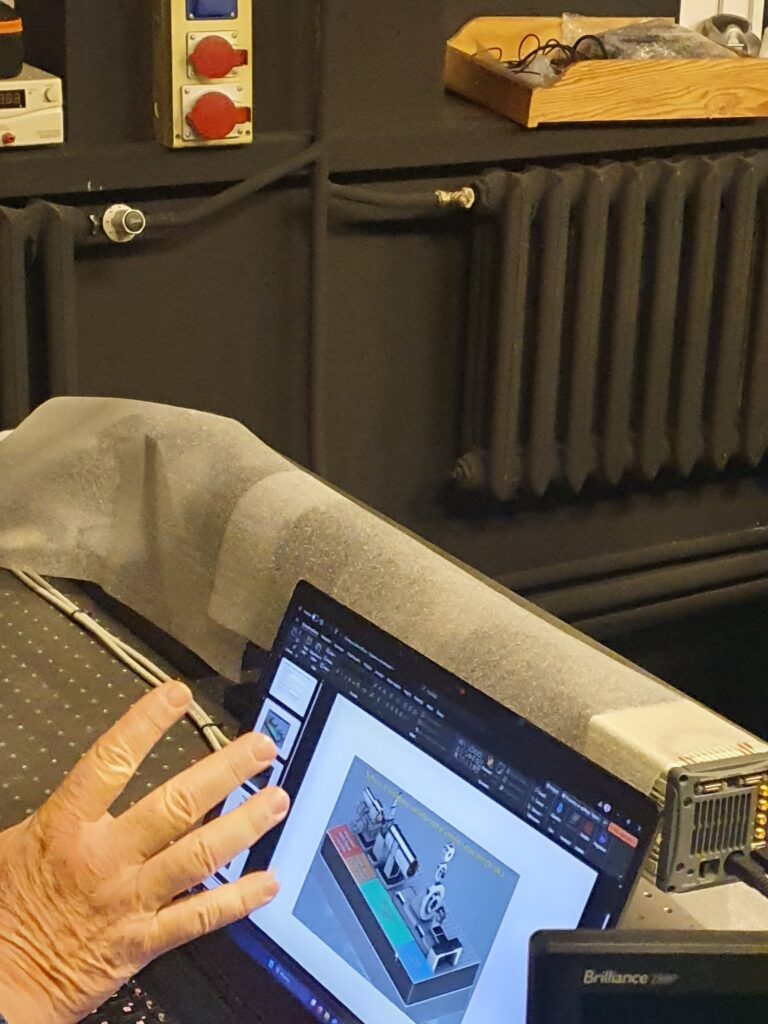

Dr Jacek Galas told the assembled participants about the ins and outs of building the PIT system and the innovative technologies used in it, based on artificial intelligence (AI) and machine learning (ML) algorithms.

The technology presented will be used to optimise the process of monitoring copper content in flotation froth. Through the use of AI technology based on advanced image recognition techniques (and its features, specific to the flotation process), it will be possible to reduce the scope of previously used much less efficient and environmentally friendly laboratory methods, which will translate into significant economic and social benefits (reduced emissions, improved safety, process optimisation, etc.).

The first tests of selected elements of the system were also carried out on a real site.

See a short film about these events:

We are now facing the first full installation, configuration and commissioning in industrial conditions in order to carry out further research on artificial intelligence algorithms and adaptation of the System to industrial conditions.

Don’t miss the next exhibitions

We will report on further technologies being developed within the Min.io project in future NEWS and on our social media depending on the progress of the laboratory and pilot work. Keep an eye on our project website and the calendar of events available there. There we will post information about future planned exhibitions.