Data Management in Future Mines – Maximizing Value from Data – summary session

Dimitris Kassimis holds a Diploma in Business Economics, and a MSc in Technologies and Services for Intelligent Information and Communication Systems. He has more than 15 years experience in IT projects for the banking Industry and in nationally-funded projects. Dimitris Kassimis combines business acumen with project management skills, having participated as a project manager in various research projects, including recent projects HEU ONELAB – Medical laboratory technology (Project Reference 101073924), HEU ODYSSEUS – Unobtrusive Technologies for Secure and Seamless Border Crossing for Travel Facilitation (Project Reference 101073910), and HEU URBREATH – Nature-based Solution for Climate Neutrality improvement (Project Reference 101139711).

Insights from the MINE.IO Workshop

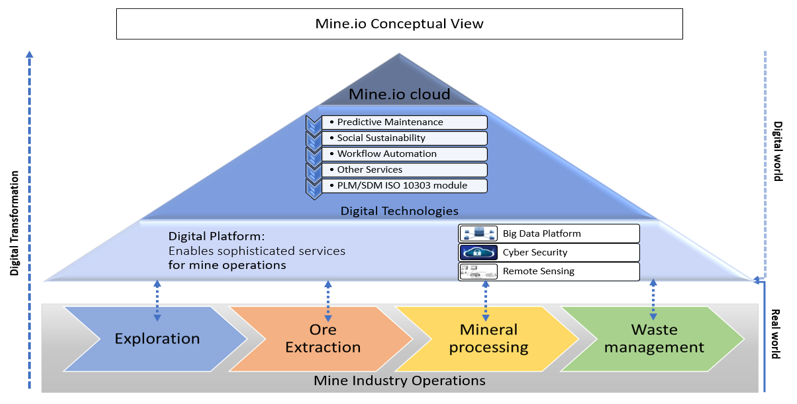

The deficient adoption of the digital advancements, indicate that the mining industry lags behind in embracing the digital transformation to a significant extent. As a result, the mining industry faces a critical juncture, that is undergoing a significant transformation, driven by the need for enhanced efficiency, sustainability, and safety. The MINE.IO platform is at the forefront of this shift, as a comprehensive digital solution designed to address the challenges of the contemporary mining Industry. To this end, the recent MINE.IO Workshop dived into details of the platform’s architecture, providing insights of the data management strategies, and its potential to revolutionize the mining Industry. A closer look of what was introduced in the context of ‘Data Management in Future Mines – Maximizing Value from Data’ is following.

Addressing Digital Maturity Challenges

One of the most significant issues that the MINE.IO platform is tackling, is the relatively low level of digital maturity. A key factor contributing to that is the legacy systems incompatibility. Outdated technology systems confront difficulties to function in proper and effective terms with the contemporary technologies. To address this issue, mining sites need to find ways to bridge the gap between legacy systems and modern digital solutions. Furthermore, the intricacy of the various heterogenous mining technologies and processes exacerbate the issue. This complexity hinders both the seamless integration of the operating systems and functionalities, and the interoperability of the diversified mining technologies. Furthermore, the diverse use cases, implementing various different scenarios and applications, intensify the problem. The siloed and undigitized mining operations refer to the compartmentalization of different aspects of mining operations, where various functions and departments within mining operations employ independently and are powerless to share data or resources effectively. Finally, the supply chain operations and the supplementary value-added solutions isolation impede the sufficient integration and coordination between mining operations and the larger supply chain, which include activities such as material acquisition, logistics, and transportation. This kind of isolation can lead to delays, inefficiencies, and a lack of supply chain awareness.

The Mine.io platform aims to overcome these challenges by leveraging a two-pillar architecture – Enterprise Premises (on-site operations) and MINE.IO Cloud (digital solutions). This abstraction layered approach is a popular design principle that helps control complexity and enhance system modularity. This layered architectural approach facilitates the separation of concerns and promotes a clear understanding of the system’s components and their interactions. This integration enables seamless data flow and real-time decision-making, paving the way for more efficient and sustainable mining practices.

Big Data Platform Architecture:

At the core of the MINE.IO platform is the Big Data Platform, which is designed to handle vast amounts of data that being generated by the mining operations. Its architecture features:

- Data Repositories: Centralized storage solutions, including MongoDB and Hadoop and individual storage solutions, for both pre-existing and new data.

- Real-Time Data Streaming: Ensures reliability across data flow, enabling real-time monitoring and decision-making.

- REST APIs: Facilitate data asset management, exchange, and sharing, supporting CRUD (Create, Read, Update, Delete) operations.

- Connectors: Enable interoperability with various storage solutions, ensuring that data can be accessed and utilized across different systems.

This architecture supports distributed data storage, scalability, and data discoverability and accessibility, facilitating the mining companies to manage and share data across their operations. The Mine.io platform’s capability to handle diverse data types and formats ensures its versatility, resulting in a robust solution for modern mining Industry needs.

Core Principles of Mine.io: Security and Interoperability

It is critical to mention that the MINE.IO platform focuses on the security by design, embedding security measures directly into the development process. This ensures that data management systems are inherently secure, protecting sensitive information from potential external threats.

Furthermore, the MINE.IO platform emphasizes on the interoperability, enabling seamless data exchange between different systems and data sources. The Big Data Platform’s asset cataloguing feature further enhances data discoverability, supporting users to find and utilize the information they demand. This approach provides interoperability with a variety of data storage solutions and, furthermore, the expandability of the Big Data Platform.

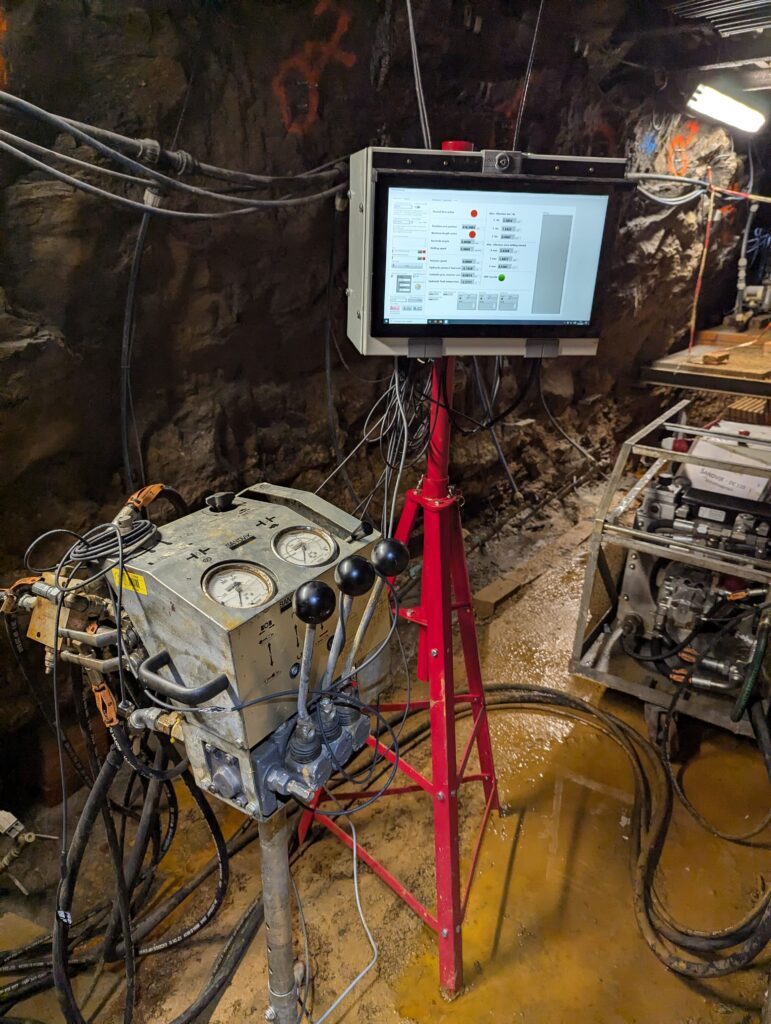

The real-world TUBAF Pilot in Freiberg

The TUBAF Pilot in Freiberg, as a key use case for the Mine.io platform, will demonstrate the platform’s ability to handle real-time data streaming, data storage, and retrieval, ensuring interoperability and reusability of data. By successfully integrating data from various sources, the pilot is going to showcase how the Mine.io platform can enhance operational efficiency and decision-making in real-world mining scenarios.

AI, IoT, and Real-Time Data Accessibility building the Future Mining

During the course of the MINE.IO workshop, the technologies that are likely to highly impact the future of mining were explored. Artificial Intelligence (AI) and Machine Learning (ML) have been recognized as the most revolutionary technologies, offering predictive insights and enabling data-driven decision-making. Additionally, IoT devices were highlighted for their vital role in real-time data acquisition and monitoring, while edge computing was recognized for its ability to process data closer to the field, reducing latency in remote mining locations.

As far as maximizing data value is concerned, the real-time data accessibility was identified as the most critical factor. The ability to access the data in real-time is of major importance for optimizing operations and improving efficiency. Interoperability between systems and data sources was also emphasized, as it ensures seamless data flow across different platforms, enhancing overall operational consistency.

New Era for Mining Operations

MINE.IO vision of a future digital mine through the development and validation of technologies and processes for the transformation of the mining industry, aligns with the contemporary trends in digital transformation, where data plays a crucial role in deriving insights and emphasis is given on data-driven decision-making and optimization within mining activities.

The thoughtful integration of all these elements suggests a dedication to addressing the specific needs and challenges of the mining sector through a well-structured and versatile Mine.io architectural framework.

The MINE.IO platform represents a significant step forward in the digital transformation of the mining industry, where technologies like AI, IoT, and edge computing will play an increasingly fundamental role in shaping the future of mining. With Mine.io ability to handle diverse data types and formats, this framework is well-positioned to lead this transformation, paving the way for a more connected and efficient mining industry.

Max Friedemann received his Master in mechanical engineering in 2021. Afterwards he started to work as a research assistant at the chair for underground mining methods at TU Freiberg. Since 2021 he is working on digitalization strategies for underground mining. His first project was the development of a decentralized communication and data acquisition system. In 2023 the European funded project Mine.io started in which Max is working as project manager as well as developer for the sub-project “digitization of the drill rig”.

Integrating Drill Rigs into the Digital Mine 4.0 Ecosystem

The mining industry has long been associated with heavy machinery, manual labour, and unpredictable environmental conditions. However, with the rise of Industry 4.0 technologies, digital transformation is revolutionising how mining operations are conducted. One groundbreaking initiative leading this change is the MINE.IO project, a European Union-funded effort focused on digitising mining processes. A key component of this project is the integration of a Sandvik DE110 exploration drill rig into a digital ecosystem, enabling real-time data analysis and predictive maintenance.

Why Digitisation in Mining Matters

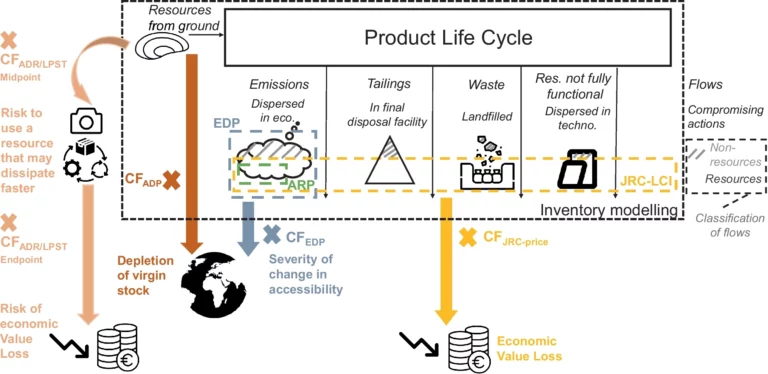

As global demand for raw materials continues to grow, mining companies face increasing pressure to enhance efficiency while reducing environmental impact. Traditional mining operations often lack the ability to monitor machines in real time, leading to inefficiencies, excessive downtime, and increased operational costs. By introducing smart technologies such as artificial intelligence (AI), the Internet of Things (IoT), and big data analytics, mining can become safer, more sustainable, and significantly more productive.

The digitisation of mining equipment enables:

- Real-time monitoring of machines to detect inefficiencies and malfunctions.

- Predictive maintenance, which helps prevent breakdowns and extend the lifespan of machinery.

- Improved safety measures through enhanced equipment monitoring and automation.

- Optimised resource extraction, reducing waste and environmental impact.

The MINE.IO Project:

The MINE.IO project is a collaboration between 25 European partners, including universities, research institutions, and technology providers. One of its primary goals is to integrate a traditionally non-digital drill rig into a fully connected mining ecosystem. This drill rig, the Sandvik DE110, has been retrofitted with a range of sensors, including:

- Displacement transducer to measure the length of the drilling and the penetration rate

- Speed sensor to measure the rotational speed of the drill bit.

- Hydraulic pressure sensors to analyse drilling force.

- Vibration sensors to detect irregularities.

- Temperature sensors to monitor hydraulic fluid.

These sensors provide valuable data that is processed in real-time using AI algorithms. The system can determine the type of rock being drilled, optimize drilling parameters, and anticipate maintenance needs before failures occur. All collected data is sent to a cloud-based platform for further analysis, allowing operators to make data-driven decisions that improve efficiency and reduce costs.

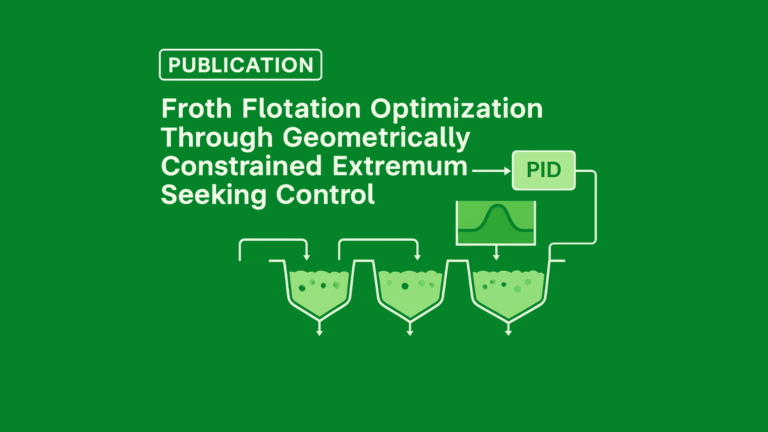

Measurement While Drilling (MWD):

One of the most promising aspects of this digital transformation is the implementation of Measurement While Drilling (MWD). This technique allows for real-time analysis of geological formations, enabling miners to make precise adjustments during the drilling process. MWD has been widely used in the oil and gas industries, but its adoption in mineral exploration is still relatively new. By integrating MWD with AI-powered analysis, the Mine.io project aims to:

- Detect transition zones and weakness areas within rock formations.

- Assess drill bit wear to optimize replacement schedules.

- Improve the accuracy of mineral exploration, reducing unnecessary drilling and increasing efficiency.

The Role of Predictive Maintenance

Maintenance costs account for 40–70% of total mining expenditures, making predictive maintenance a crucial advancement. Traditionally, equipment is serviced at fixed intervals or after a breakdown occurs, leading to unnecessary downtime and increased costs. Predictive maintenance, powered by AI and machine learning, allows for:

- Early detection of machine wear and tear, preventing sudden failures.

- Optimized maintenance schedules, reducing unnecessary servicing.

- Extended equipment lifespan, saving significant operational costs.

The MINE.IO project’s predictive maintenance system uses historical and real-time data to forecast potential failures, ensuring that necessary repairs are conducted proactively. This shift from reactive to proactive maintenance can dramatically improve operational efficiency and minimize downtime.

The Road Ahead

The integration of the Sandvik DE110 drill rig into the MINE.IO ecosystem is a significant step toward the future of mining. The first phase of implementation has already demonstrated improved drilling precision and core sample quality. However, further data collection and refinement of AI models will be essential to fully realize the benefits of digital mining.

As the mining industry continues to embrace digital transformation, innovations like real-time data analysis, predictive maintenance, and MWD will become the norm. By leveraging the power of Industry 4.0, the sector can achieve higher productivity, enhanced safety, and a reduced environmental footprint.

The MINE.IO project exemplifies how technological advancements can revolutionize traditional industries, paving the way for a smarter and more sustainable future in mining.

Let us know what you think in the comments and share your thoughts with us!

Leave a Reply