MINE.IO at the 23rd Slovak-Czech-Polish Optical Conference

The 23rd SLOVAK-CZECH POLISH OPTICAL CONFERENCE was held in Štrbské Pleso, Slovakia, from September 2-6 2024, and focused on wave and quantum aspects in contemporary optics.

For over 40 years, the Polish-Slovak-Czech Optical Conferences provide a forum for presenting newest research results and exchange of knowledge and ideas within the academic and industrial communities of Poland, Czech Republic and Slovakia.

During the 4 days of the conference, one could listen to a number of interesting invited presentations, as well as contributions in spoken or poster sessions. The topics of these presentations included such areas as:

- quantum and nonlinear optics

- wave and geometrical optics

- optical communication and information processing

- lasers and laser-assisted manufacturing

- life sciences and health

- lighting and displays

- metrology and sensors

- XUV optics

- design and manufacture of optical components

- education for research and training in optics

On the first day of the conference, there was a presentation session titled “New Trends in Photonics” during which one of the partners of the Minie.io project, Łukasiewicz Research Network – Tele and Radio Research Institute, had its presentation in the section devoted to the topic of “Wave Optics”.

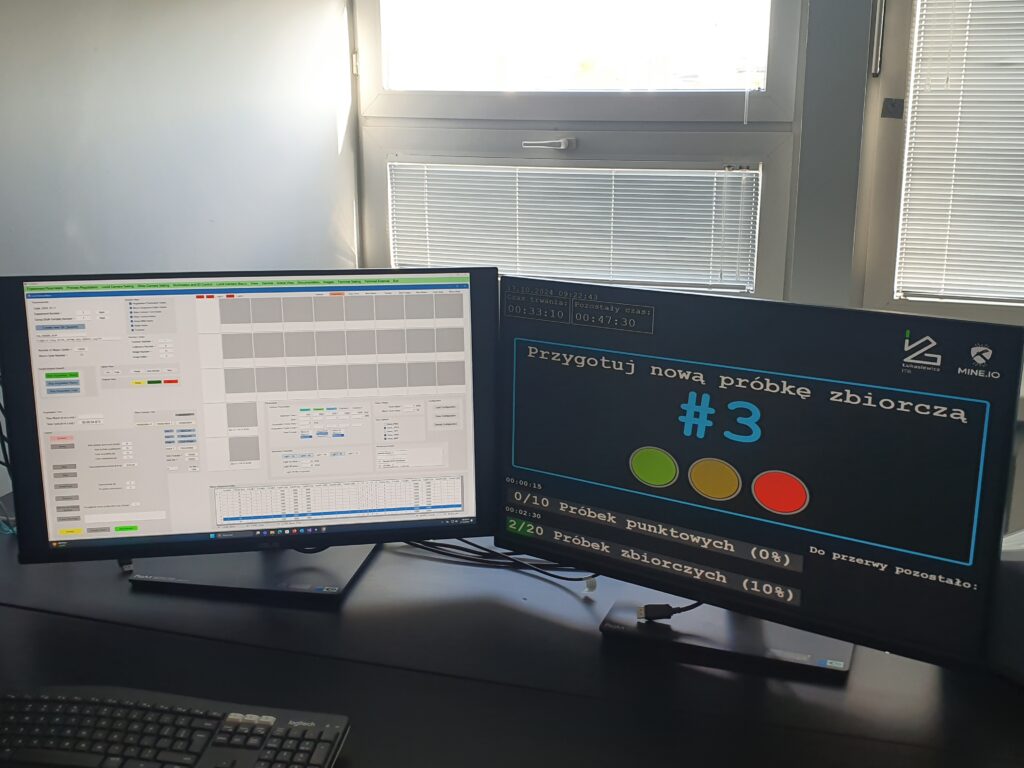

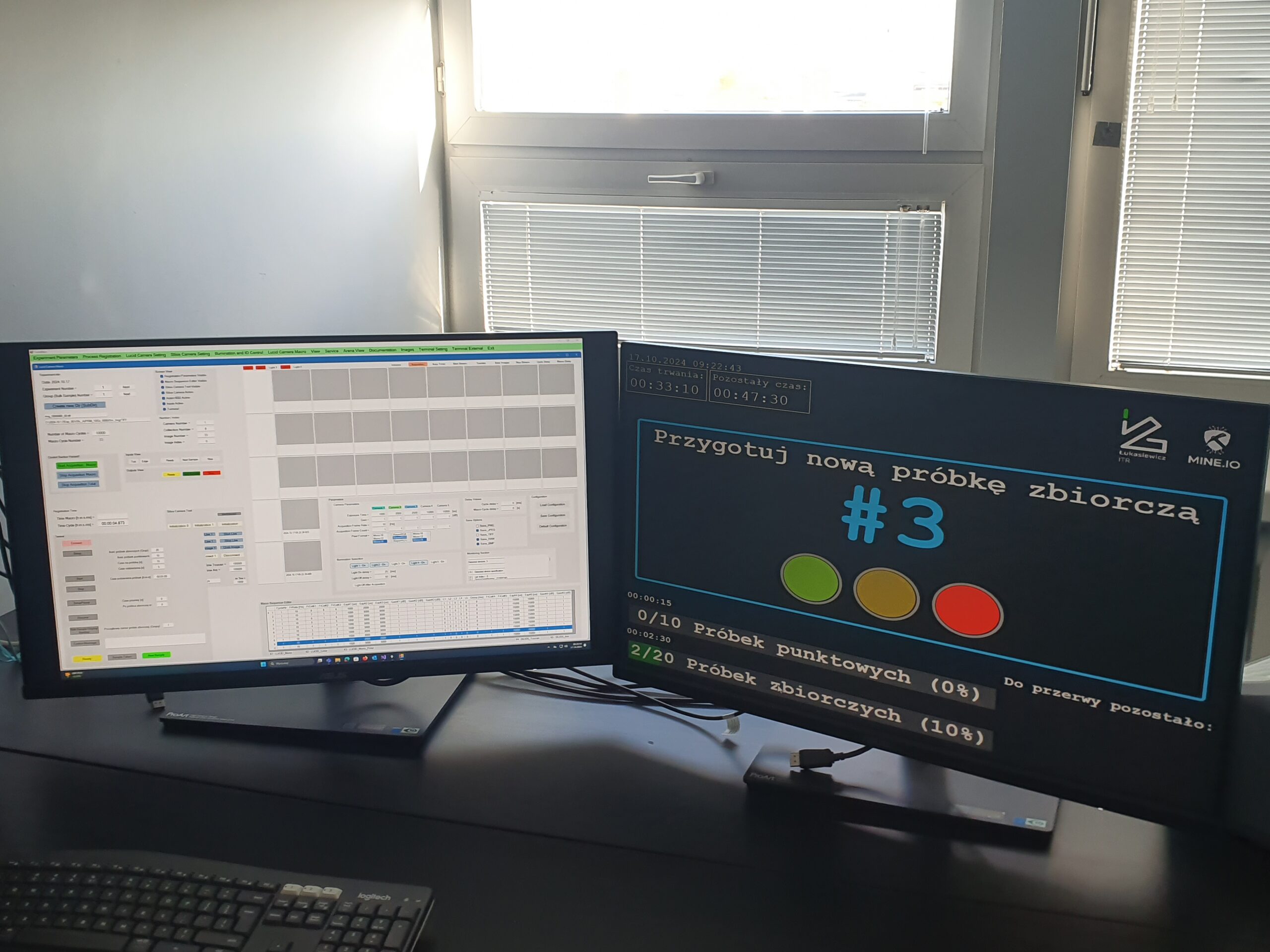

Jacek Galas of Łukasiewicz – ITR, on behalf of a team consisting of representatives of L-ITR, L-EMAG, AGH and KGHM, talked about innovative photonic solutions that, combined with advanced Artificial Intelligence (AI) and machine learning technology (ML) , may revolutionize the mining industry in the near future.

This team, as part of the Mine.io project, explored, among other things, the LDA (Linear Discriminant Analysis) application in the ML (Machine Learning ) process. The ML algorithms have their origins in the classification algorithms. They are constructed on the basis of training groups of data and enable us to classify the unknown data to one of the training group. Theoretically, if we have more training groups we should be able to obtain more accurate estimation of data. However, such approach is not efficient. Each of training group should have a high number of data sets, which in most cases is difficult to obtain. Therefore, during the study, a different approach to estimating flotation froth in a mineral processing plant based on analysis of froth surface images was proposed.

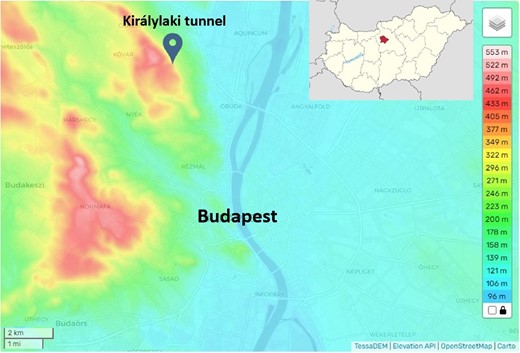

As our expert said: ”The experiment was performed in the Pb Mineral Processing Plant. The images of the flotation froth surface were registered for seven technological conditions of the flotation process. The flotation parameters were stabilized 30 minutes before the image registration process. The images registered in the stabilized technological conditions constituted the training group of images for the ML process. For each of the technological conditions of the flotation process 10 froth samples were captured for chemical content analysis. This means that each of 7 training groups of the froth images contained 10 subgroups of images with well-defined froth content. The ML process enabled us to construct the froth content estimation algorithms for the flotation process in the experiment.”

You could learn about this and many other aspects of this approach from the presentation below, which was given during the conference:

Thanks to the entire Team for your invaluable contribution to the sustainable development of the mining and processing of key minerals industry by building a Digital Mining 4.0 Ecosystem.