Smarter Ways to Study Rocks, Drill Cores and Use Drilling Data

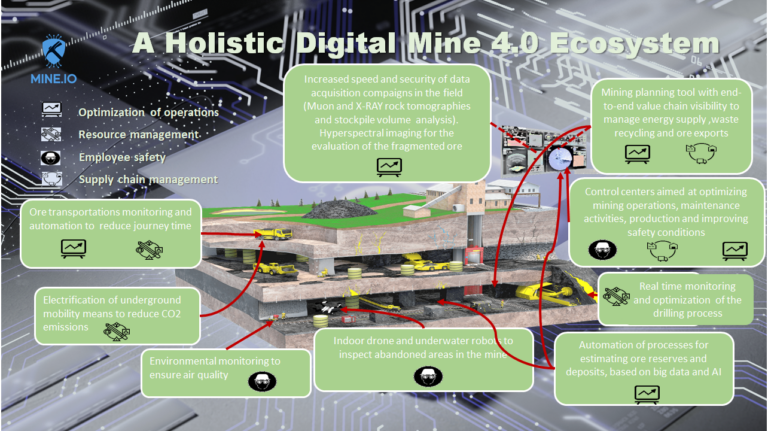

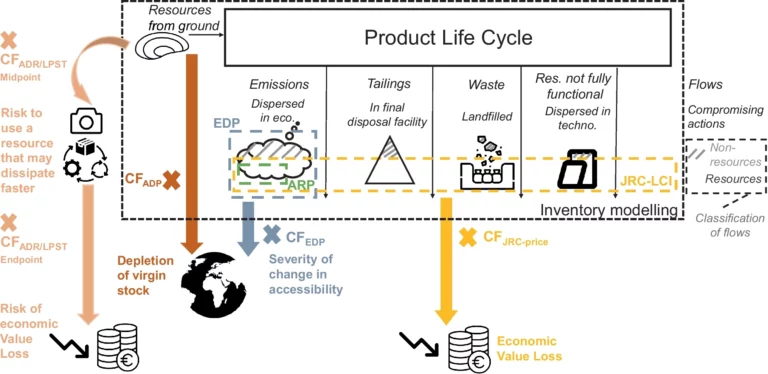

Understanding what’s underground is where all starts, and the first step to successful and sustainable mining, Usual ways of studying drill cores or tracking drilling data can be slow, costly, and not always accurate. Innovative technologies under the Mine.io project introduces modern solutions to assess these problems: better drill core knowledge is obtained by scanning it, using advanced imaging methods, and smart use of drilling data through live monitoring then processing by artificial intelligence (AI) gave us information on the go about physical properties while drilling. These tools can help us see underground materials more clearly and improve how we drill which is usually a costly process.

Better Drill Core Scanning with Imaging Technology

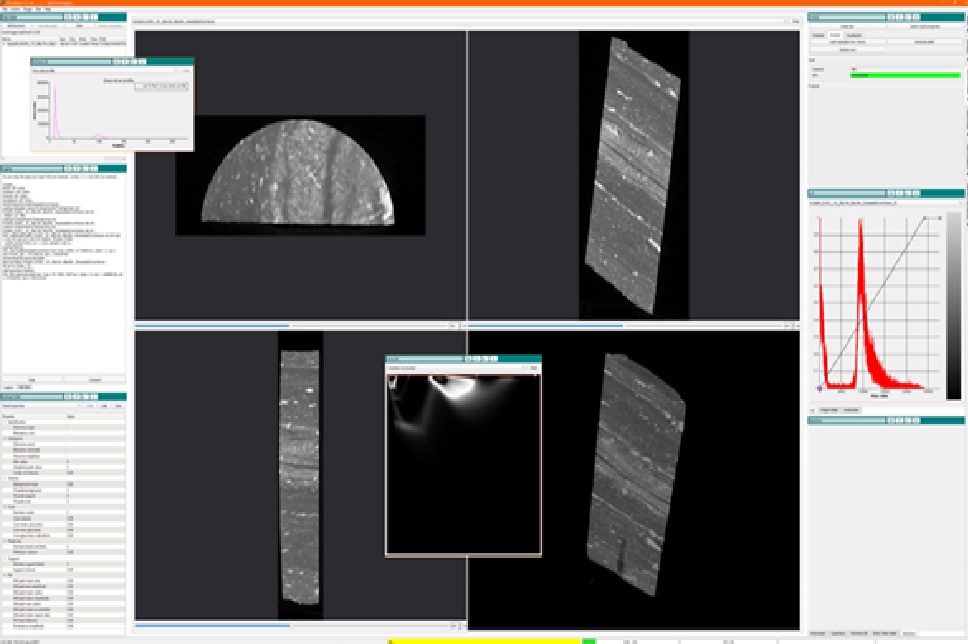

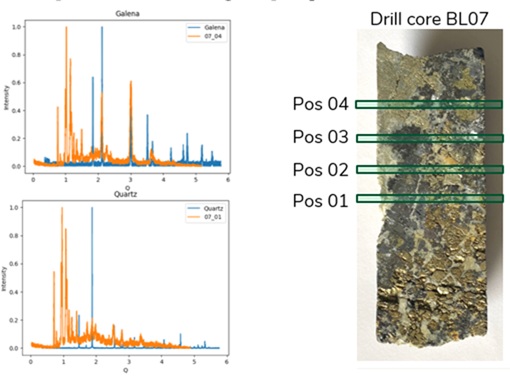

This task focuses on using advanced, non-destructive scanning methods, like X-ray diffraction, X-ray scattering, and CT scanning to study materials (rocks) obtained from drill cores without directy intervening them. Portable tools scan whole cores to capture detailed 2D and 3D images of their internal structure and material composition.

Small samples are used to ensure accuracy with callibration, and the data is manually entered and improve to train AI systems that can then automatically identify features such as cracks or specific minerals among other rock’s features. The result is a faster, more accurate analysis that helps detect valuable resources and reveal geological potential underground.

What is generated by this:

- Clear 2D and 3D images showing what’s inside the drill cores.

- Faster, non-destructive testing for accurate drill core analysis.

- Better data for detecting specific minerals or features highlighting hidden problems underground.

Why It Matters:

This method saves time, avoids damaging valuable samples, and helps mining teams make faster and more informed decisions.

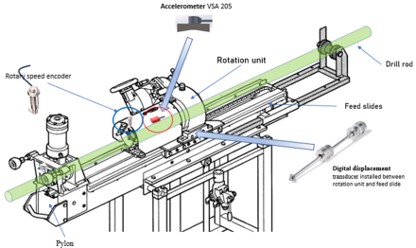

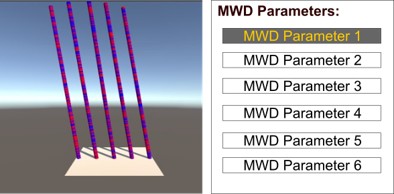

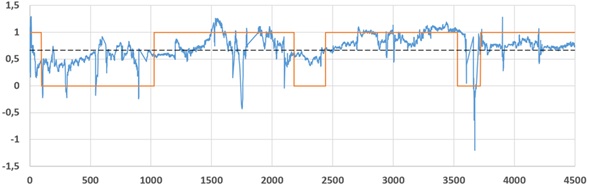

Drill monitoring, extracting data and Using AI improve drilling

This task focuses on extracting and analysing data on the go, then using AI to turn the large amounts of data collected during drilling (known as Measurement While Drilling, or MWD) into clear, useful insights about the rock that is being drilled. By building tools that clean and analyze data automatically, creating virtual models to test and plan drilling strategies, and developing systems to monitor equipment health, the goal is to improve accuracy, safety, and efficiency. These AI-driven tools help predict underground conditions, reduce equipment failures, and support smarter decision-making, leading to smoother drilling operations with less downtime and better use of resources.

Why It Matters:

This approach helps drilling teams work more efficiently and safely. It also means fewer unexpected problems, less downtime, and smarter use of resources. The more important approach is that on the pilot site this technology will classify ore vs waste as drilling is advancing.

For more information on the advanced technologies developed by Mine.io for analysing drilling data, see the article: ‘Data Management in Future Mines – Maximising Value from Data – summary session’.

See also a short film about the work on the pilot installation:

Summary and What’s Next

Together, these two tasks advanced core scanning and smart data while drilling are changing the way we explore what’s underground. They bring more speed, accuracy, and safety to mining and geological work.

Next Steps:

- Run pilot tests to see how well the tools work in the field.

- Use real-world results to improve the technology.

- Apply these tools to more types of mining projects.

These new tools aren’t just solving today’s challenges they’re helping shape a more efficient and sustainable future for mining and geology.

This work is supported by the European Union’s Horizon Europe programme (Grant #101091885), which funds projects that bring innovation to the mining industry.

WP3 – Eco-efficient technological solutions for exploration, electrification and extraction

T3.3 X-ray scattering and computed tomography (Leader: FhG)

T3.6 CPS for system drill behaviour (Leader: LTU, Contributor: AMDC]

Stay tuned, more articles from the Progress Work Campaign series will be coming soon…