Predictive Maintenance as the emerging maintenance paradigm in the mining sector

In the mining sector, equipment maintenance expenses are reported to account for approximately 40% to 70% of total setup costs and 20% to 60% of operational expenses. Rather than being viewed merely as a routine operational task, maintenance is increasingly recognized as a strategic function, essential for sustaining high levels of production efficiency. Within this context, maintenance represents one of the few controllable cost areas in mining. However, compared to other industries, mining has yet to fully leverage emerging technologies that enable predictive maintenance, which could significantly minimize equipment downtime and enhance overall operational performance.

The Predictive Maintenance component of the Mine.io platform uses data-driven methods to analyze condition monitoring data in real-time, to detect the early signs of asset degradation, to predict upcoming equipment failures, and to provide actionable insights that support informed, proactive decisions for critical assets such as drilling machines, thus enabling timely and cost-effective maintenance, often before any physical symptoms appear.

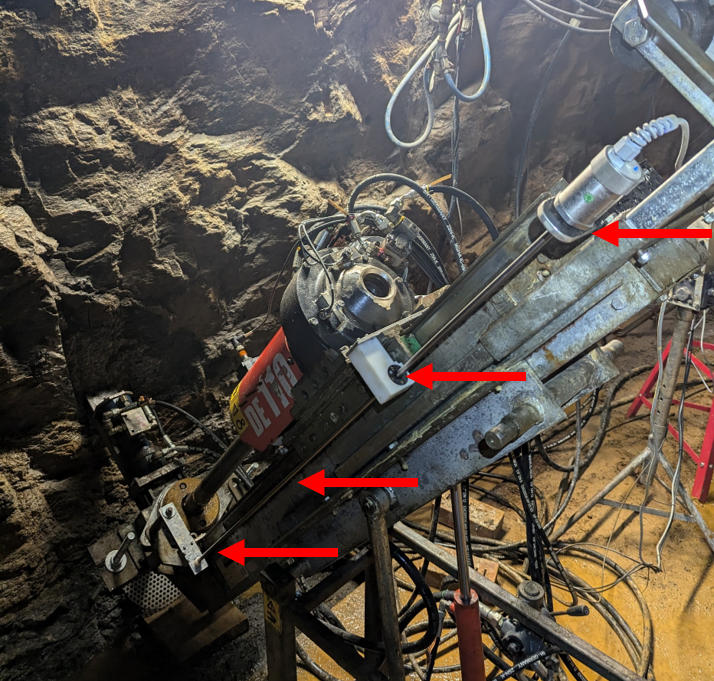

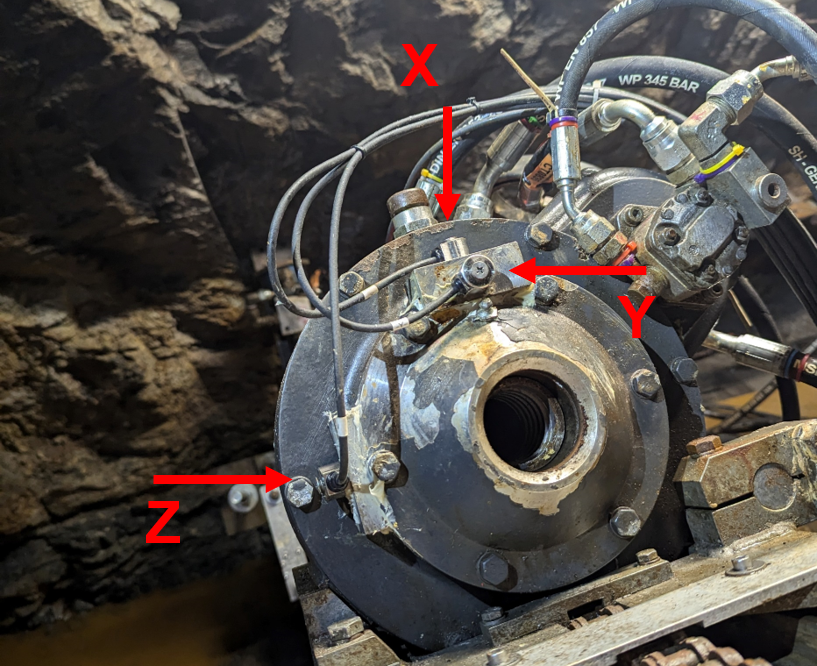

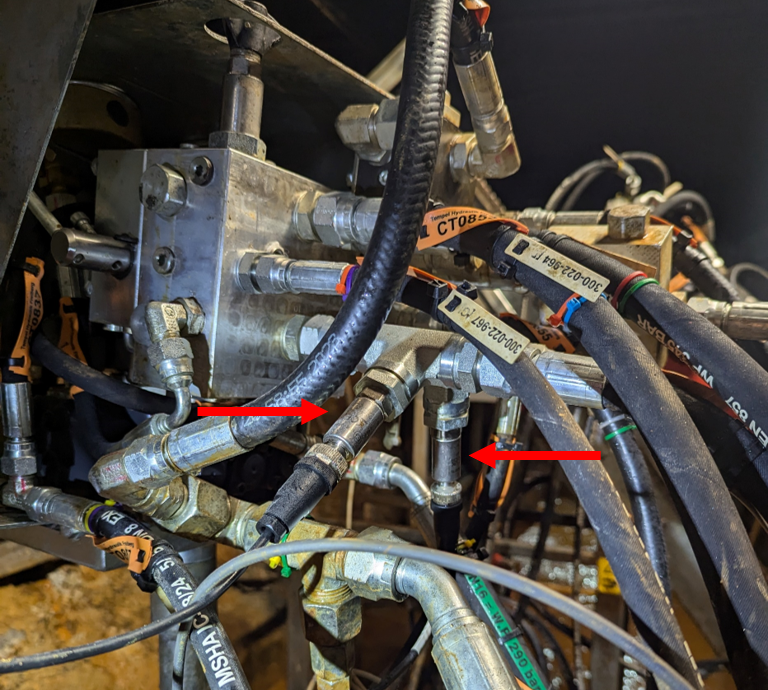

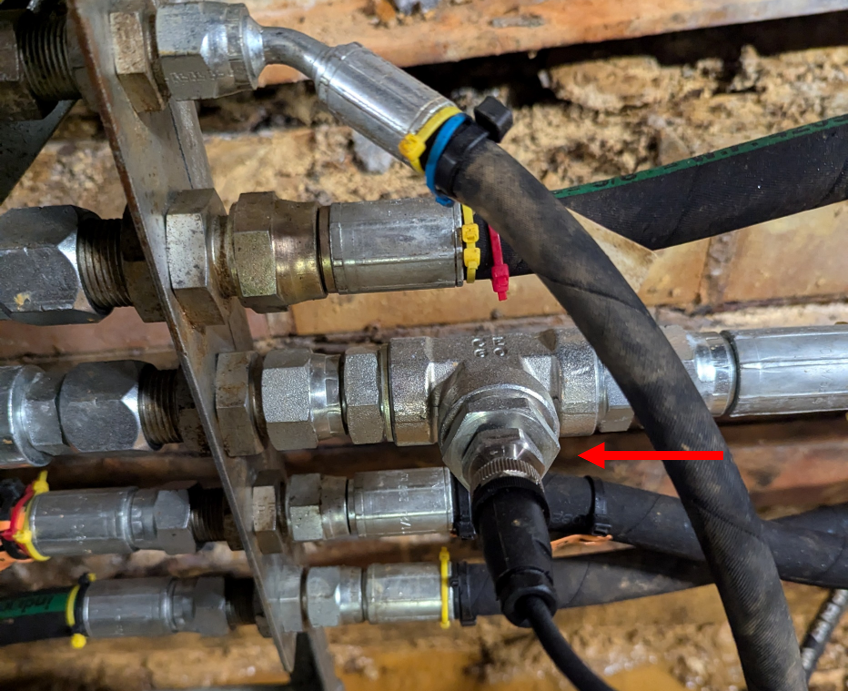

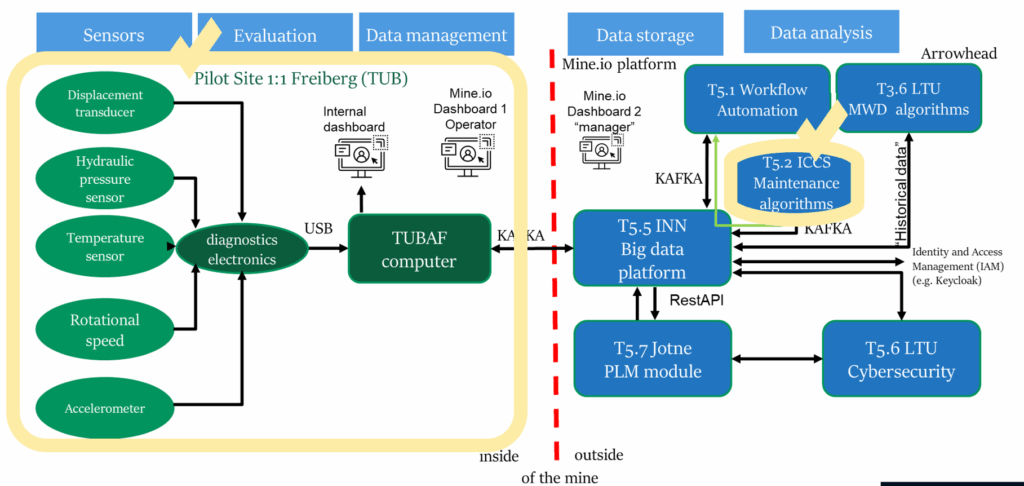

The pilot installation for research and predictive modelling is based on a drilling machine equipped with appropriate sensors and is being tested at the Technical University Bergakademie Freiberg (TUBAF).

The Predictive Maintenance component is implemented as an Autonomous Analytics as a Service platform that simplifies the creation of intelligent, data-driven applications. It automates the full lifecycle of Machine Learning (ML) and deep learning workflows – from design and configuration to execution and deployment – enabling more efficient and scalable development of advanced analytics solutions that incorporate descriptive, predictive, and prescriptive analytics.

Its technical architecture allows users to configure custom analytics tasks via an interoperable interface. It supports storage and management of algorithms and models, integration of heterogeneous data sources, and delivery of high-quality analytical outputs. At the same time, it reduces development time and effort, democratizes the use of sophisticated ML tools for users without thorough expertise, and enhances productivity for data scientists. In this way, it contributes to more reliable predictive maintenance outcomes by optimizing model performance and improving prediction accuracy.

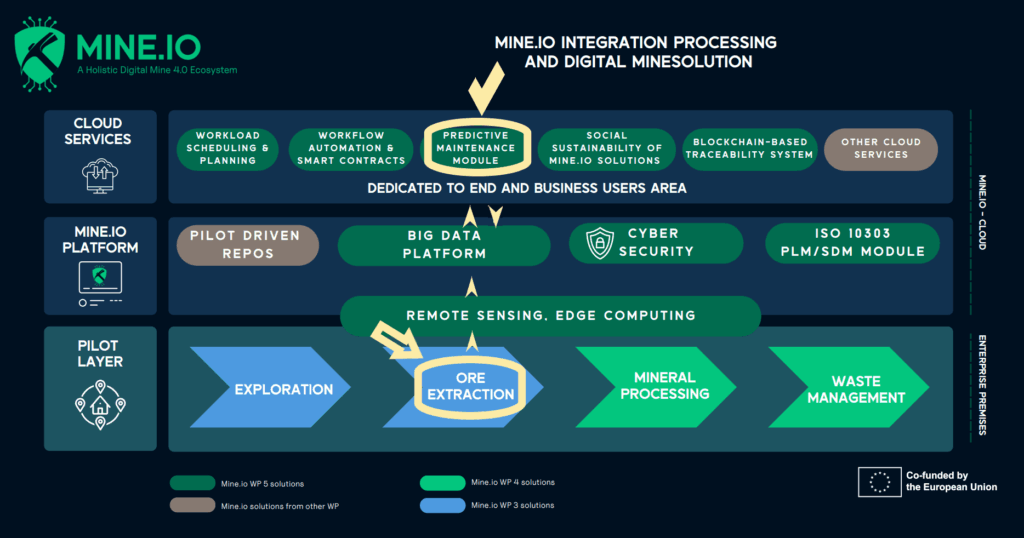

WP5 – Mine.io integration processing and digital mine solution

T5.2 Predictive maintenance, net zero carbon and continues development (Leader: ICCS, Participants: GFT, INN)

Stay tuned, more articles from the Progress Work Campaign series will be coming soon…